Extremely weird issue after Melzi to RAMPS conversion.

Hello,

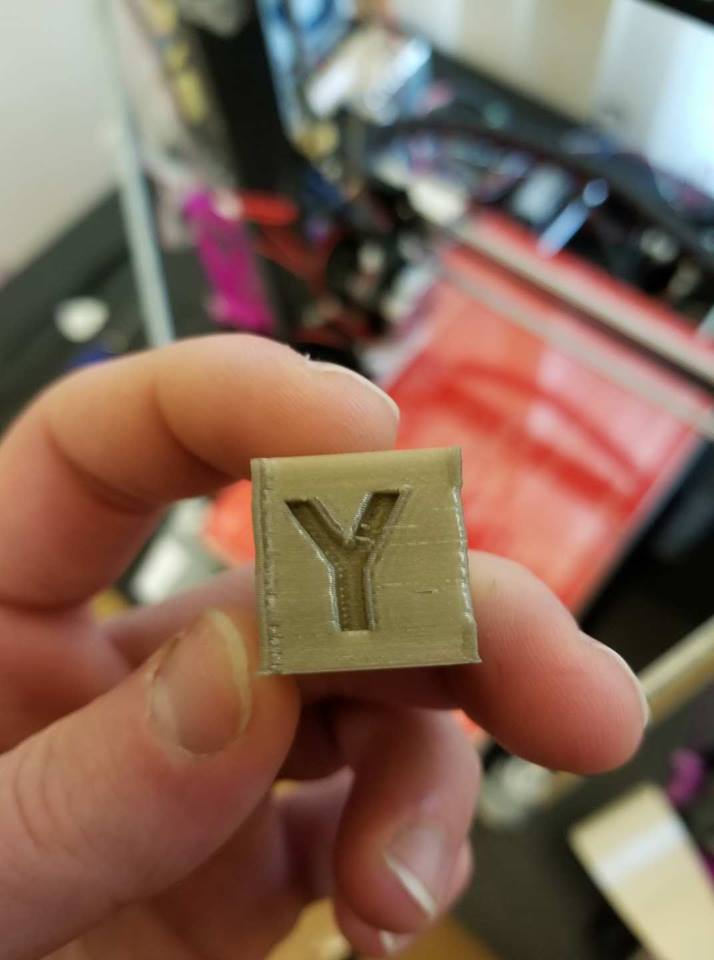

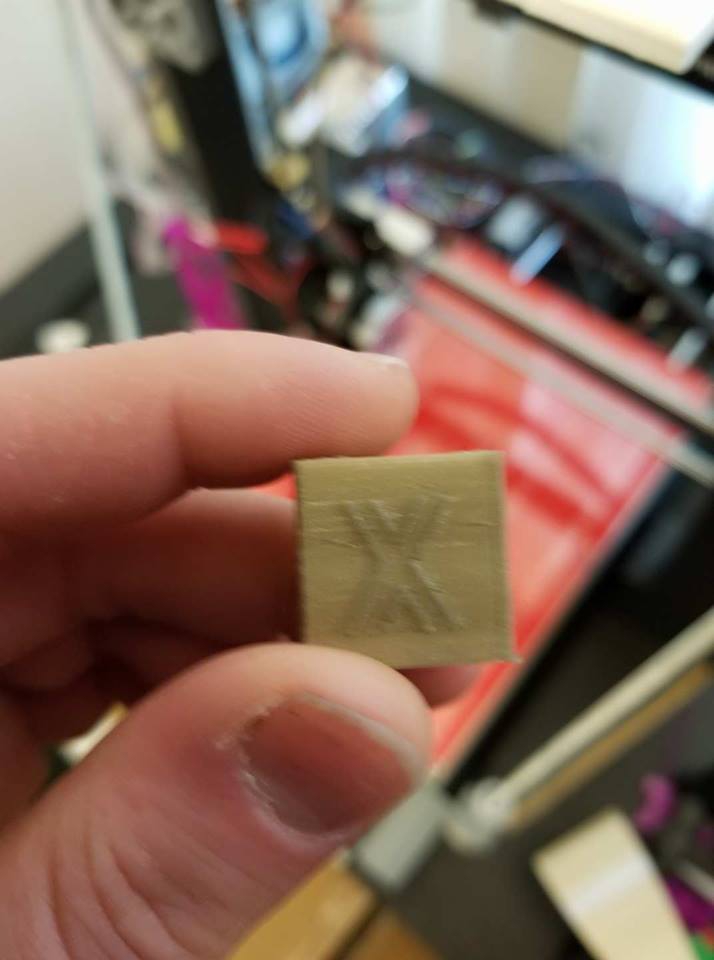

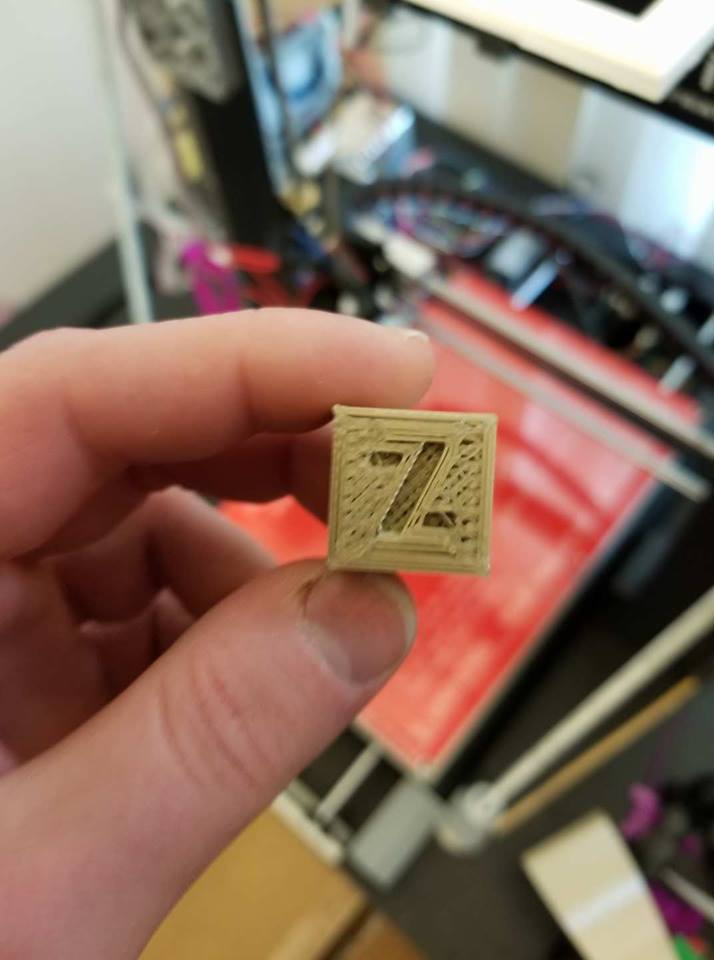

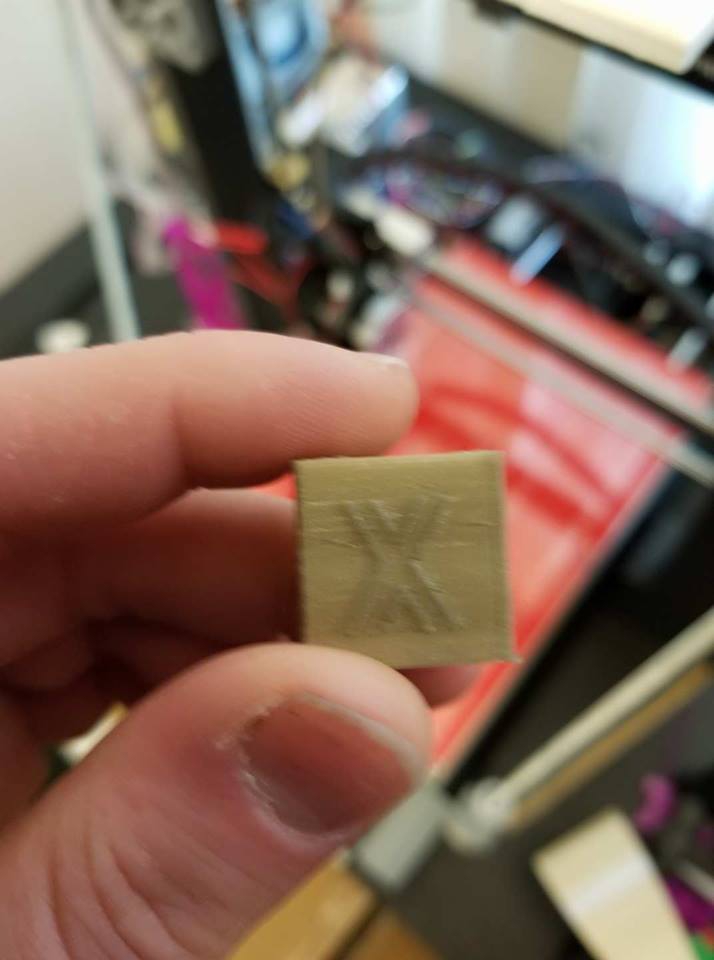

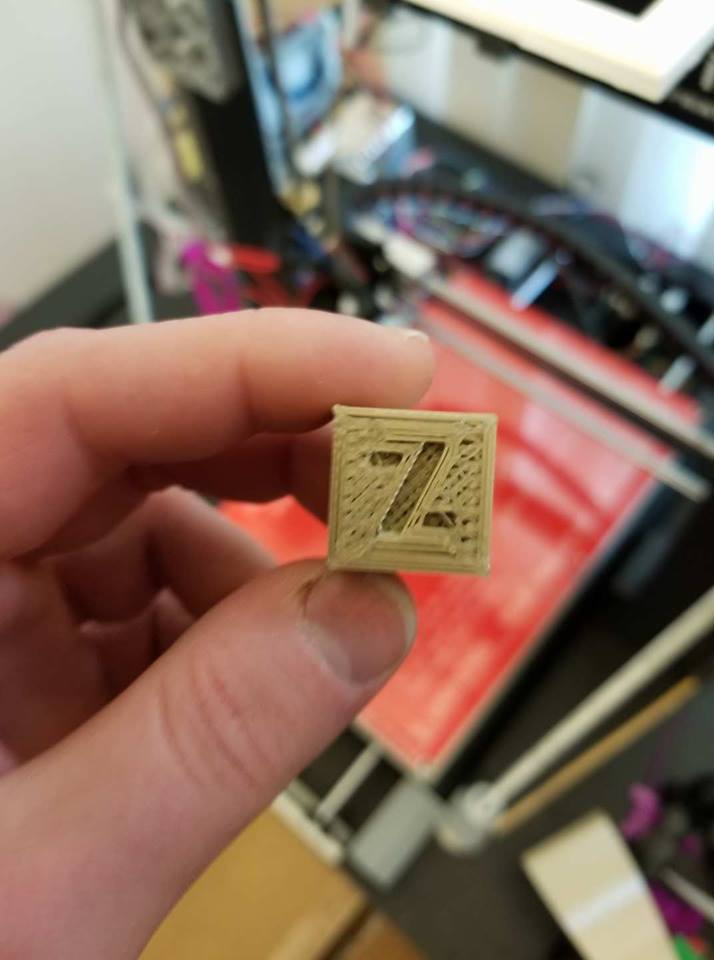

I have this problem with a Wanhao Di3 converted to RAMPS 1.4. I followed the instruction on the 3DPrinterWiki and after awhile I got it mostly working. I'm getting this problem where the X side of the 20x20x20 cal cube is to the left and the indent isn't deep, the Y side is too deeply indented and to the left, and the Z side is an incomplete Z shape and the top layers aren't completely filled.

The printer has z-braces, its solid, I reduced the accel settings by half and reduced jerk from 20 to 8. Motors are working fine, no weird noises, and belt tension is nominal. My print speed is usually 40, but tried to go lower to no better print. I know I have a bit more extruder e-step tuning to go, but all the motor e-steps have been tuned and the cal cube is reading 20mm +/- 0.05mm. Other mods include 200x300 bed and an outer frame/mounting system to replace the Wanhao control box.

Any suggestions to what can cause this?

Just to see, I tried printing out a low-poly Totodile, and it came out with the back with parts of the back wall printed away from the rest of the model, leaving these gaps on the left side. The right side came out fine, though (I also ran the model through netfabb's repair to be sure it wasn't the model).

I have this problem with a Wanhao Di3 converted to RAMPS 1.4. I followed the instruction on the 3DPrinterWiki and after awhile I got it mostly working. I'm getting this problem where the X side of the 20x20x20 cal cube is to the left and the indent isn't deep, the Y side is too deeply indented and to the left, and the Z side is an incomplete Z shape and the top layers aren't completely filled.

The printer has z-braces, its solid, I reduced the accel settings by half and reduced jerk from 20 to 8. Motors are working fine, no weird noises, and belt tension is nominal. My print speed is usually 40, but tried to go lower to no better print. I know I have a bit more extruder e-step tuning to go, but all the motor e-steps have been tuned and the cal cube is reading 20mm +/- 0.05mm. Other mods include 200x300 bed and an outer frame/mounting system to replace the Wanhao control box.

Any suggestions to what can cause this?

Just to see, I tried printing out a low-poly Totodile, and it came out with the back with parts of the back wall printed away from the rest of the model, leaving these gaps on the left side. The right side came out fine, though (I also ran the model through netfabb's repair to be sure it wasn't the model).

Comments

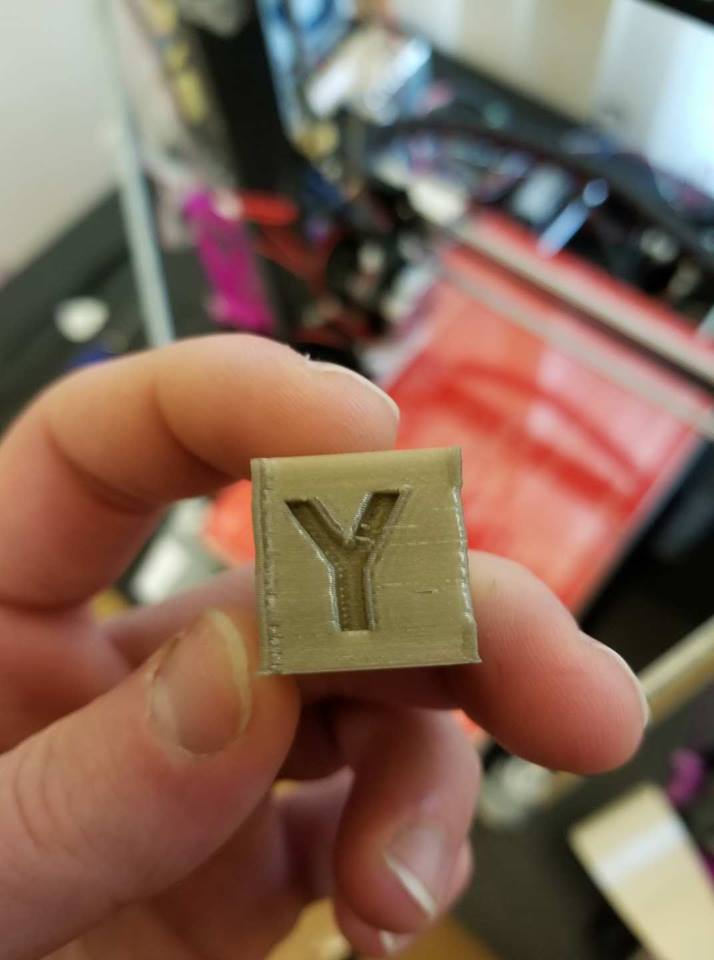

Comparisons: Left is the last one and Right is the fixed. The biggest significant change I found was that the X indent became more defined. Even though it still isn't as deep as the Y or the Z, and hard to see, but the new X indent's walls are more straight with a 90 degree angles, unlike the last cube where the walls were rounded off from the backlash.

Also, the new cube's corners are closer to straight 90 degrees.

if you look at the structure you can see clearly it´s underextruded , that also causes the deep "Y" , the flat"X" and the open surface on "Z".

think you should first calibrate the extruder(if not already done) then increase Flowrate respectively adjust Filament Parameters in slicer

https://www.thingiverse.com/thing:1278865 ;

As a last source compile with backlash correction and set x backlash to 1mm - looks around that value and see if it gets better. If it does try remove the physical source which will give the better prints.

https://www.thingiverse.com/thing:1278865

I just spent the last two days going over everything. Mechanically, everything should check out. Reflashed the firmware and have a new Micro-Swiss hot end on the way (just in case), and put in an upgraded Mk10 extruder gear and will try and recalculate extruder steps.

With that said... Another curious problem I had with calculating e-steps is that when I mark the filament at 100 or 120mm, like all the tutorials suggest, it moves more than 120mm into the extruder and can't get the second measurement. So, I've been marking at 200, and still moving 100, and going from there. Thats probably a problem within itself, but I couldn't find anything online about that. (note: Feedrate is set 3mm/s)

Is the x beld under good tensions? Loose belts would also lead to backlash and all printers have a belt tightener to resolve this issue.

X became perfect, but no matter what I set Y backlash the backlash was never in ranges of the test. So I tried a new stepper driver and somehow screwed the RAMPS board. I'm getting to my wits end on it. Everyone makes this sound so simple and I'm getting all these crazy problems that the solutions don't work. I have another RAMPS coming it, and if that doesn't work, I'm just reverting this back to original Melzi. At least that board actually works.