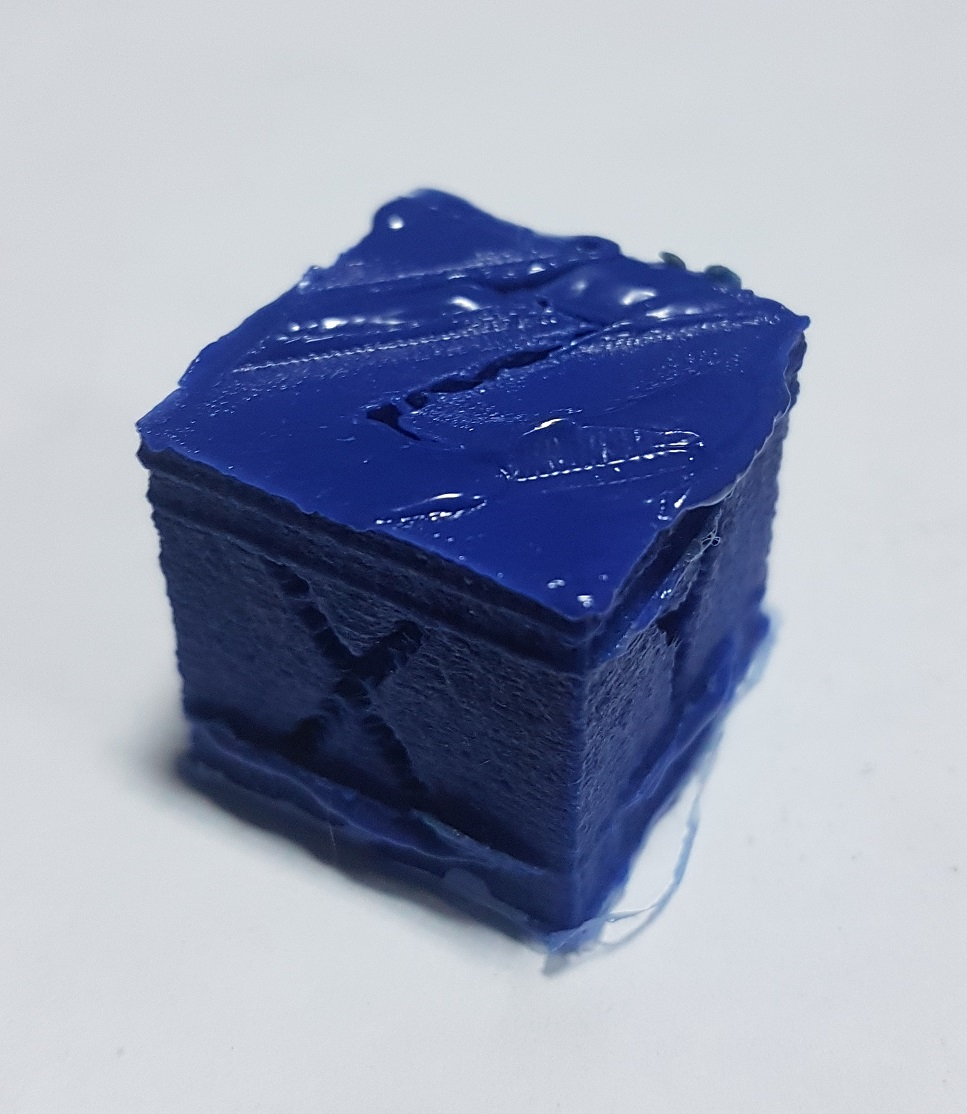

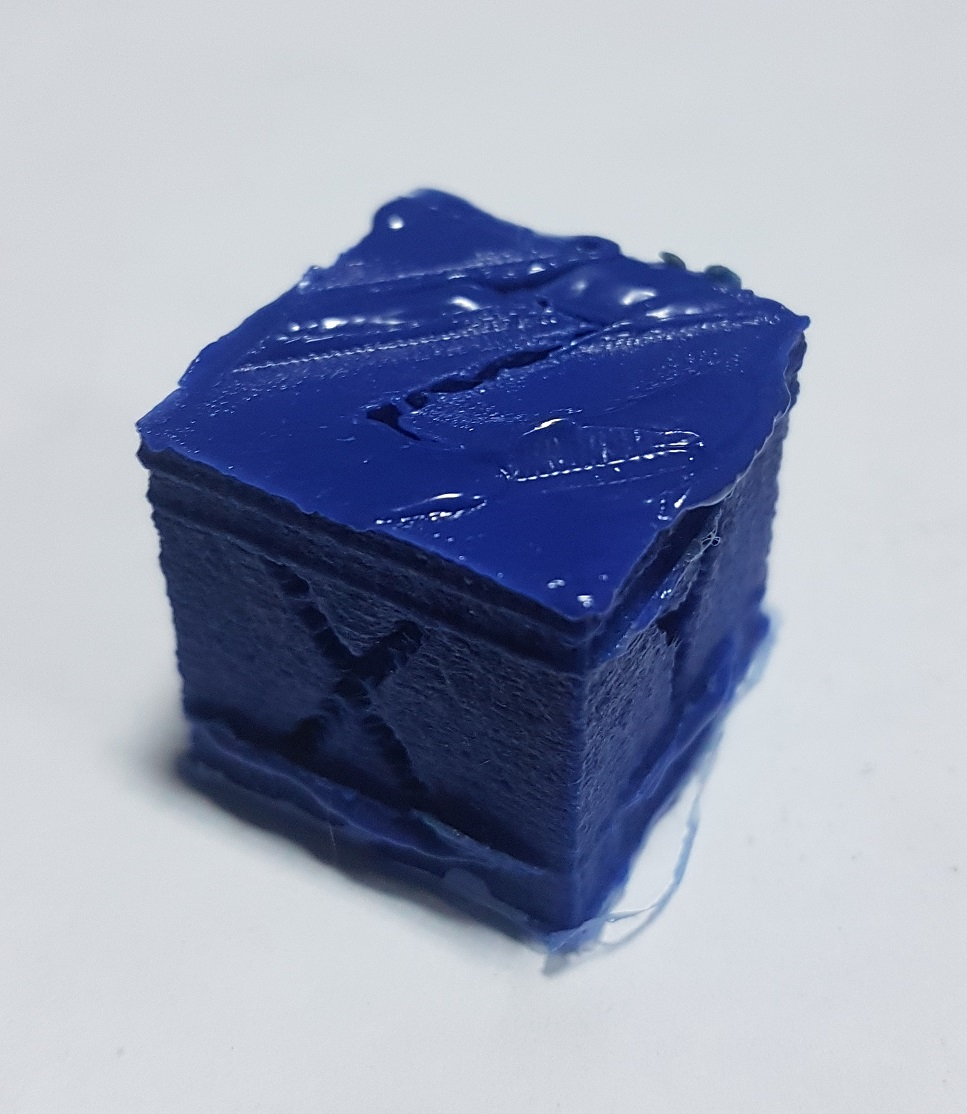

Calibration Cube printed very bad

Hi,

I am new to 3d printers. I have built a P3 steel and using Slic3r and repetier to print.

The calibration cube x y z printed bad. And I need some help. I would like to learn where is the faults and what to do to have a perfect print.

Just 5 mins before the print is finished the top side (z) was looking great. I have no idea what happened in the last 5 mins to ruin the top of the print.

Any suggestions from experienced user will be highly appreciated.

Than you in advance.

I am new to 3d printers. I have built a P3 steel and using Slic3r and repetier to print.

The calibration cube x y z printed bad. And I need some help. I would like to learn where is the faults and what to do to have a perfect print.

Just 5 mins before the print is finished the top side (z) was looking great. I have no idea what happened in the last 5 mins to ruin the top of the print.

Any suggestions from experienced user will be highly appreciated.

Than you in advance.

Comments

I think you have pure overextrusion, meaning you pushed more filament then needed and that stuff has to go somewhere. You need to calibrate extruder steps per mm first so that if you say extruder 10mm you see 10mm going in.

Then you need to find the filament specific multiplier. PLA expands a bit when being heated so you normally have a factor of 85% or 0.85 in slicer to have it extrude correct. See slic3r.org documentation for calibration of extrusion factor. They also have a test object to calibrate it.

The dimensions of the cube is correct.

I will follow the instructions on extruder calibration. and write if not solved.

Thank you for your help