Initial Delta Value Setup

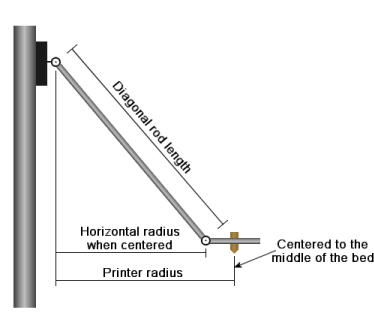

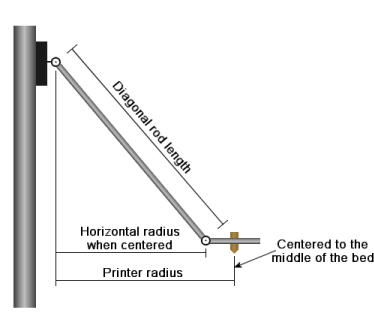

I'm having issue's setting up a home brew delta, The information that I have input into the config doesn't seem adequate for what a delta printer needs. The setup seems surprisingly vague. Yes there are pictures like a value for printer radius (which doesn't have an input). There is no Delta Smooth Rod, Carriage Offset, Effector Offset. I have put my values into the printer and they do not seem level during transition moves. The printer is "square" and have had limited success with Marlin (just cant dry print) with the moves being level and consistent. This is the information that I input

Z length 200.0 mm << Should be Usable height

Diagonal rod length 210.0mm << No brainier picture makes that easy to figure out

Horizontal radius when centered 125.0mm << If I'm reading this correctly should be the Delta Radius not to include Effector or Carriage

Floor Safety margin << No clue what that is

Max Horizontal Radius 90mm << should be half of your horizontal print area

Angle of column A/B/C << didn't touch, should be 120 off for a circle but a triangle has 180 degrees ?

Radius Error Column A/B/C << didn't touch

Diagonal rod Error Column A/B/C << didn't touch (I think should be used to compensate for slightly longer or shorter rods)

If you open the config.h file there is the ability to input effector and carriage off sets but no support to show what the intention of the values are. I figure if it was important it would be part of the web input. I'm not trying to fine tune yet to within a miniscule.000mm. I'm trying to keep the print head from drooping 9mm to the corners. I would blame it on the machine except I've been able to get it to not vary more than 1mm with Marlin.

Z length 200.0 mm << Should be Usable height

Diagonal rod length 210.0mm << No brainier picture makes that easy to figure out

Horizontal radius when centered 125.0mm << If I'm reading this correctly should be the Delta Radius not to include Effector or Carriage

Floor Safety margin << No clue what that is

Max Horizontal Radius 90mm << should be half of your horizontal print area

Angle of column A/B/C << didn't touch, should be 120 off for a circle but a triangle has 180 degrees ?

Radius Error Column A/B/C << didn't touch

Diagonal rod Error Column A/B/C << didn't touch (I think should be used to compensate for slightly longer or shorter rods)

If you open the config.h file there is the ability to input effector and carriage off sets but no support to show what the intention of the values are. I figure if it was important it would be part of the web input. I'm not trying to fine tune yet to within a miniscule.000mm. I'm trying to keep the print head from drooping 9mm to the corners. I would blame it on the machine except I've been able to get it to not vary more than 1mm with Marlin.

Comments

Can somebody please post a sample configuration.h file for a generic reprap delta printer, so I have a clean starting point.