Model Missing Layers When Slicing

Yesterday, the model had all of its layers when slicing it. The problem was that the filament was not stocking to teach layer (just a bit). I made some chances and now today only the first or just the two first layers get sliced and printed. I've tried Cura and it does the same thing.

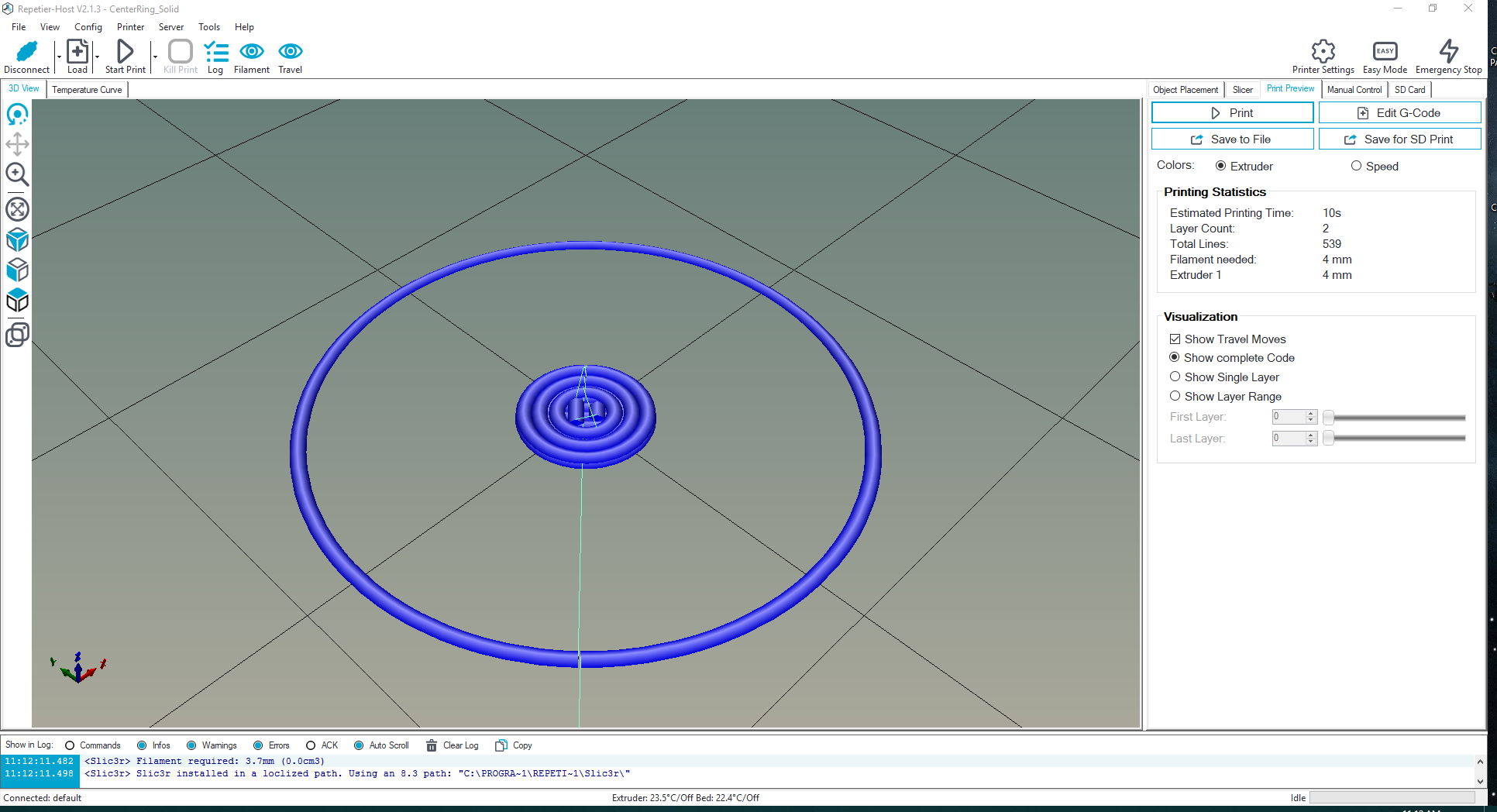

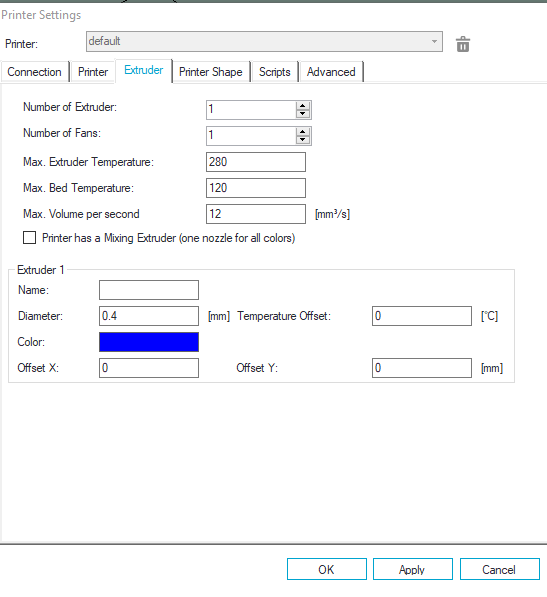

This is with the Slic3r

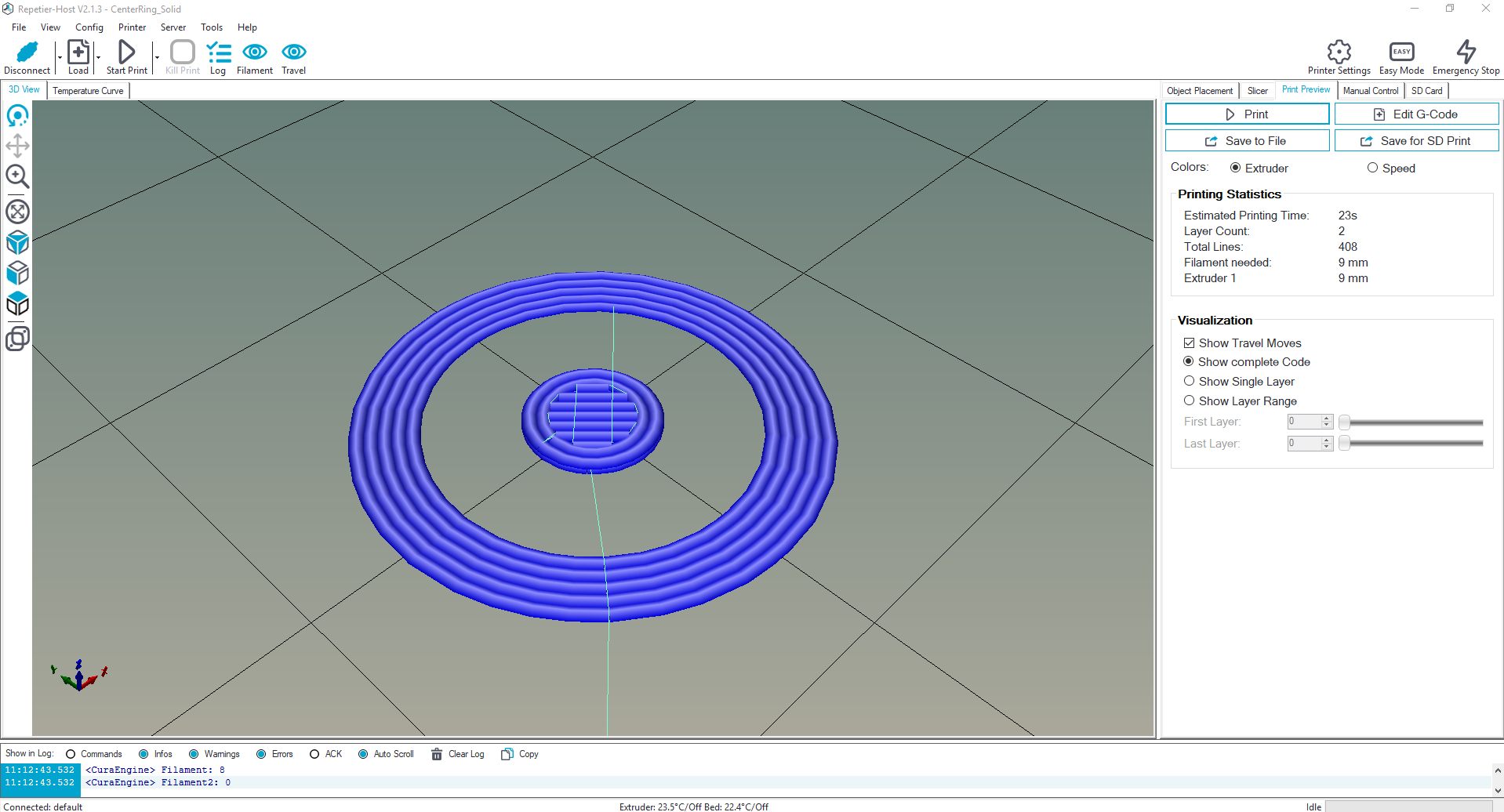

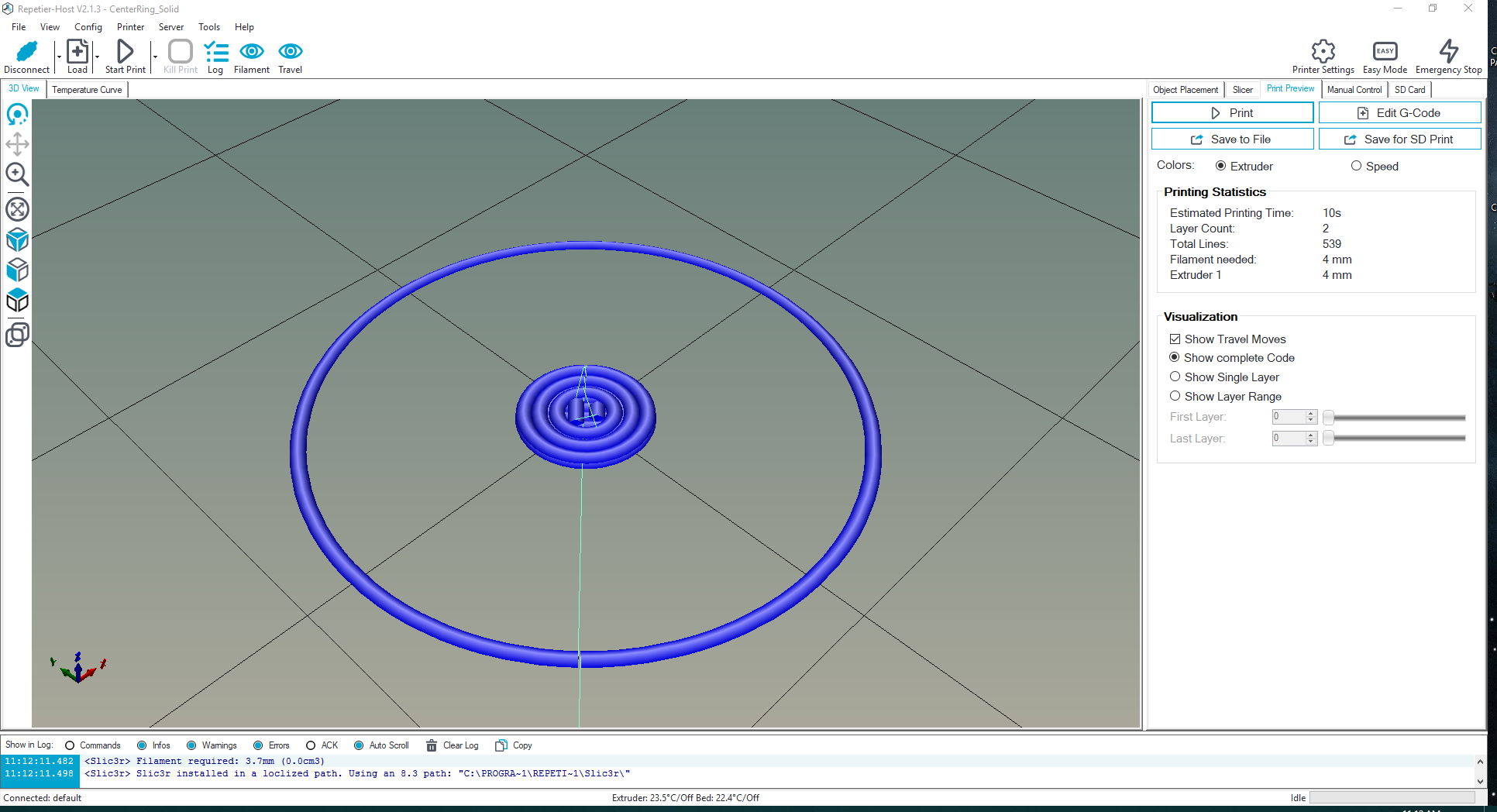

This is with CuraEngine

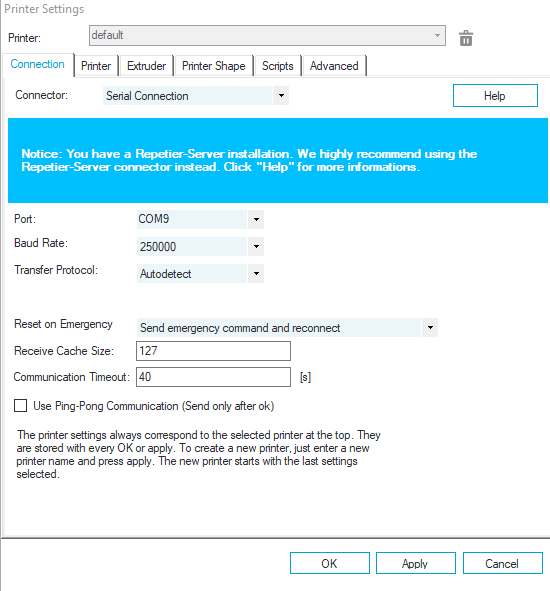

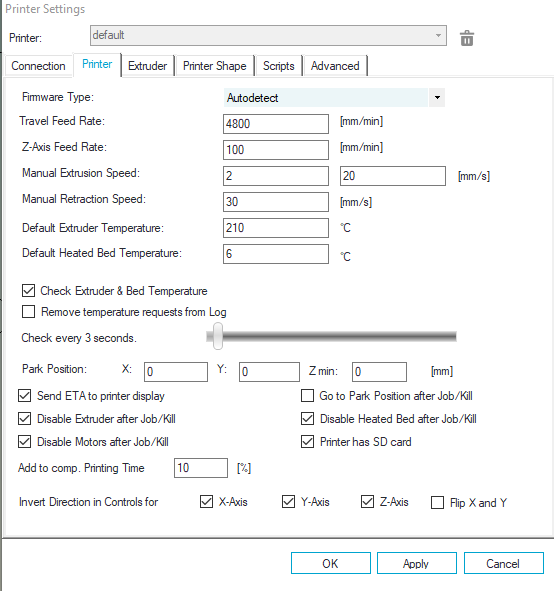

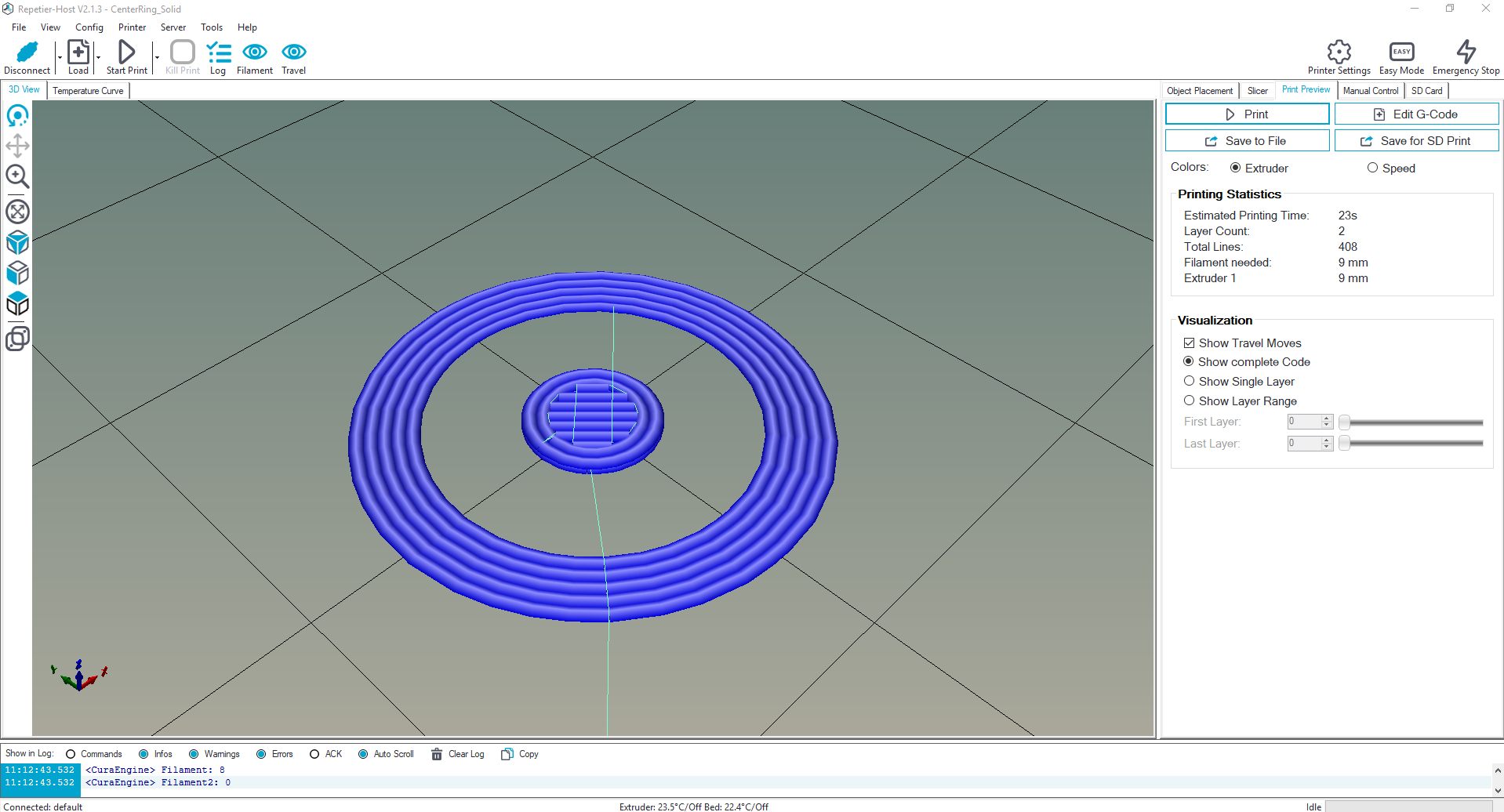

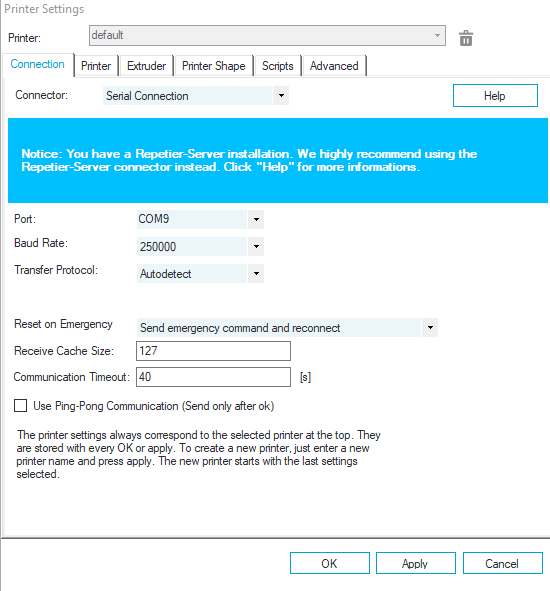

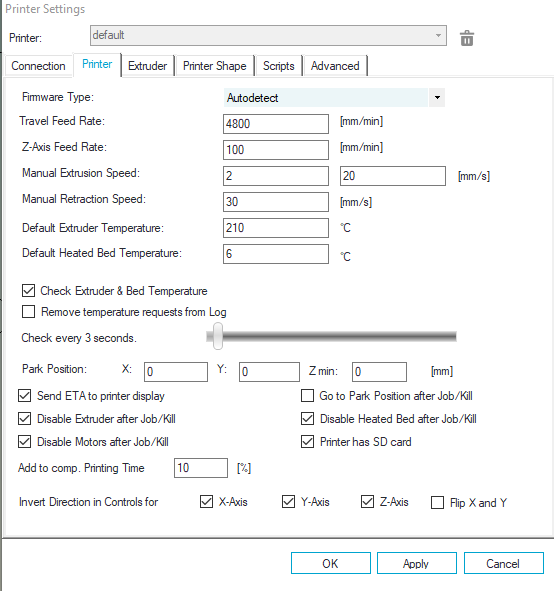

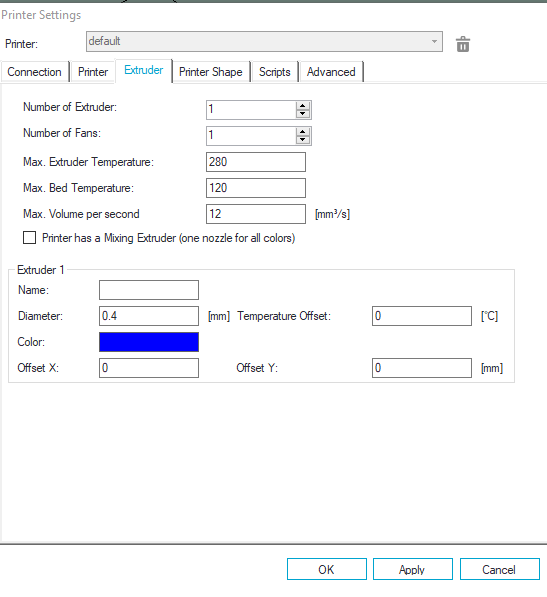

These are my printer settings

Please, let me know how can I fix this.

This is with the Slic3r

This is with CuraEngine

These are my printer settings

Please, let me know how can I fix this.

Comments

Could it be that you need to scale the object to your expected size? You can set import dimensions which defaults to mm, but if you draw in inches you need to scale with factor 25.4 to get full size you expect.

There are many helps you can put on bed to improve. BuildTak for example helps most filaments stick. Sometimes even too good. Combined with heated bed it works great. Water soluble glue sticks or some kind of hair spray (or a special 3d printer adhesion spray if you want to be on save side) are also told to work.

Extruder temp: 210

I have glass on top of the bed.

I'm using 0.2mm. I tried 0.3mm but still does the same.

G92 E0

G1 E50 F60

and measure distance again. Difference must be close to 50mm. I think you will get less so change steps per mm in eeprom for extruder to

newValue = oldValue * 50 / measuredDifference

Then repeat. After that extrudion is normalized as slicers expect it. Also make sure extrusion multiplier in slicer is set correctly. For PLA 0.85 - 0.90 (=85-90%) is a typical value. Then it should look much better.